As a full service manufacturer, Industrial Fabricators Inc. has the capacity to take a customer drawing and quickly deliver a product that is fully fabricated, finished, assembled, packaged, and ready for use.

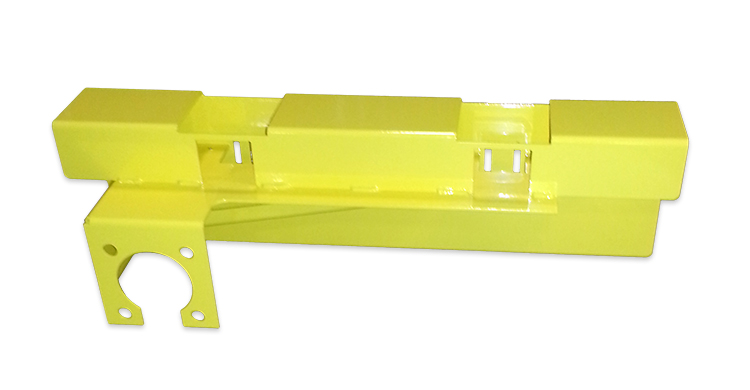

Used to mount an electronic eye, we fabricated the bracket shown here from 0.120 in. thick hot rolled pickled and oiled steel sheet. Primary processes included laser cutting and press brake forming as well as tapping the internal threads, welding the components together, and grinding to a uniform dimension. Prior to powder coating, we masked off the threads and executed a 7-stage cleaning process to ensure optimal bonding of the safety yellow finish.

Measuring 22.50 in. in length, the bracket was dimensionally inspected to confirm we met the ± 0.3 mm tolerance requirement. Intelligent planning and diligent monitoring the multi-stage manufacturing cycle ensured we met the 3 week delivery deadline.

If you would like more information about this project or the processes we used to produce it, contact Industrial Fabricators today.